DVR

Member

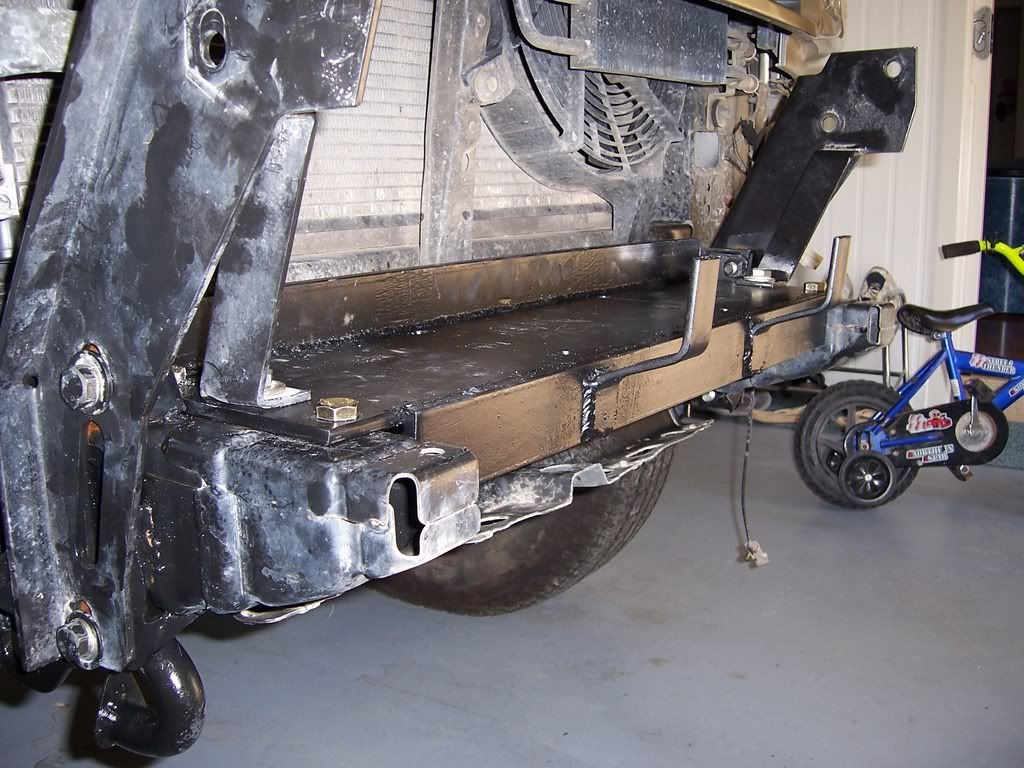

Having seen the winch that ALDI are selling I was lamenting only having a factory STR alloy bar, but then I got to thinking "What's the difference between a winch bar and a non winch bar?" I figure the winch cant be mounted directly to an Ally bar cos Both the the bar and those concertina mounts wouldn't handle 9000lb pulling on them, they would twist like crap. So I figure they must mount to the chassis some other way and the cable only passes through the bar via the fairlead.

How do they mount?

Anyone ever look into converting a STR bar to fit a winch in behind it?????

Just so you know I'm a fitter by trade and I fabricate both in steel and aluminum for a living so If it's possible I'm sure I can do it. It's just I'm just a complete noob when it comes to winches and how they work on and around a bullbar.

How do they mount?

Anyone ever look into converting a STR bar to fit a winch in behind it?????

Just so you know I'm a fitter by trade and I fabricate both in steel and aluminum for a living so If it's possible I'm sure I can do it. It's just I'm just a complete noob when it comes to winches and how they work on and around a bullbar.

(after hours of course

(after hours of course )

)