joshman

Member

As with my other DIY brake write-up, if you have ABSOLUTELY ANY doubts about performing this work yourself, then don't do it, it's not worth it if you do it wrong. Employ a professional to do it. Another thing. Take your own photos through out the whole process of dismantling, it'll make it a lot easier to work out how it all goes back together.

Materials:

- Brake Shoes (part#: N1726)

Tools:

- Garden Hose

- brake cleaner

- Rags

- Pliers

- Needle-nose Pliers

- Flat Blade Screw drivers (one large, one small)

- 'Fasty' strap (cam-buckle tie-down)

- Big Hammer

- 2x Chassis Stands

The tools:

First things first, park your truck on stable flat ground, chock your front wheels, ideally in front, because as you jack up the rear of the car, the weight will shift forwards. Crack the nuts of your rear wheels both sides before you jack the car up. Jack up the rear axle and put your chassis stands under the u-bolt brackets. and rest the rear axle on that. Make sure the handbrake is off.

pull the wheel off the side you're working on. i put the wheel down in a manner that i could sit on it as i worked. with the wheel off, you're presented with the Drum Hub.

The hub might be held on with some small screws, or not, either way, the hub might be a little hard to remove. if it is difficult, give it a few good hits with the hammer to loosen it up and pull the drum off.

after pulling the drum off, hose the entire drum out. brake dust is quite bad for your health, DON'T USE A BRUSH. the hose is your best option.

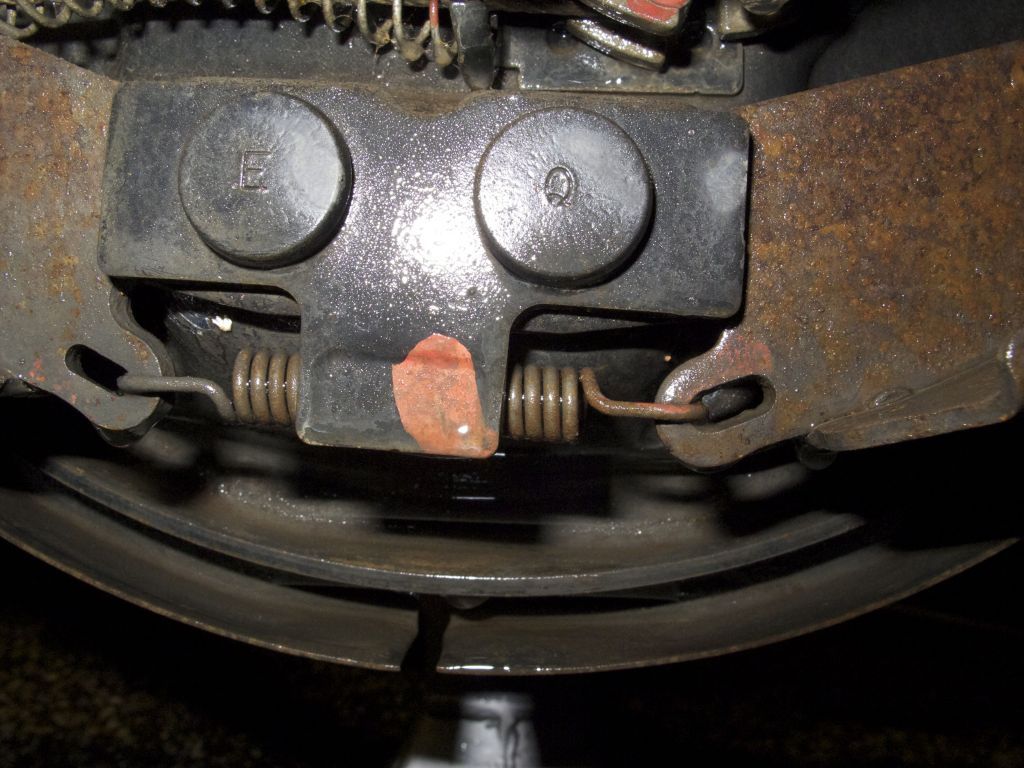

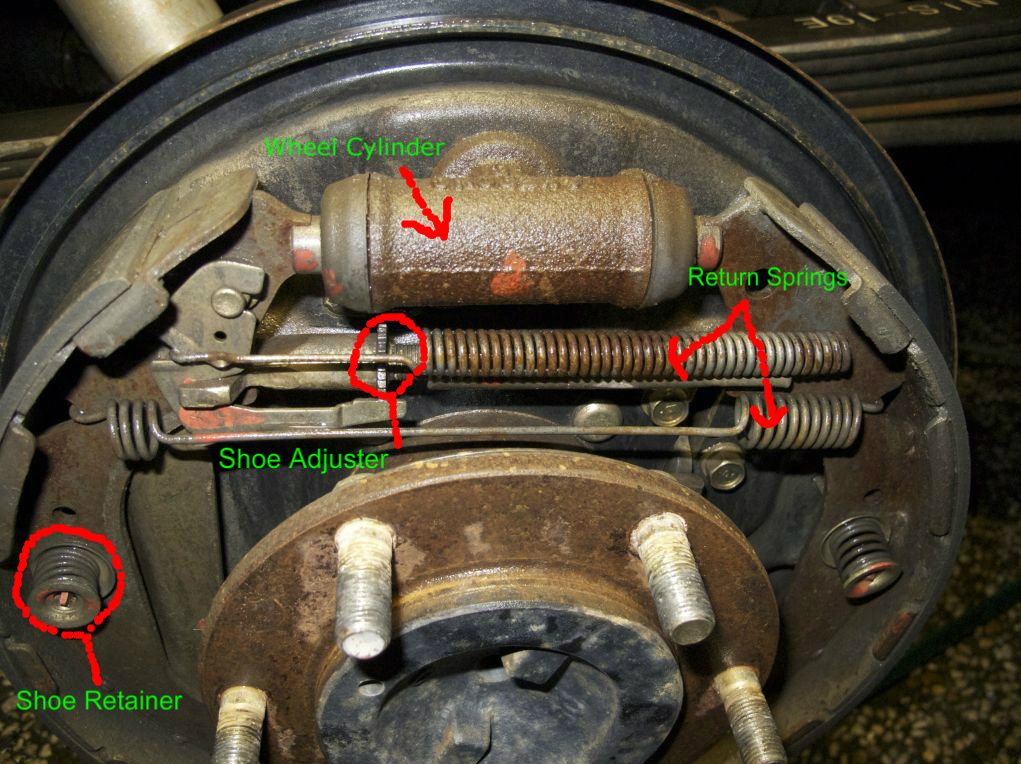

This is what a drum brake looks like. The first step is to loosen off the braking system so you can remove everything, the method i used is to lift the little holding pin and use the needle-nose pliers to wind the shoe adjuster back to remove tension from the springs.

Materials:

- Brake Shoes (part#: N1726)

Tools:

- Garden Hose

- brake cleaner

- Rags

- Pliers

- Needle-nose Pliers

- Flat Blade Screw drivers (one large, one small)

- 'Fasty' strap (cam-buckle tie-down)

- Big Hammer

- 2x Chassis Stands

The tools:

First things first, park your truck on stable flat ground, chock your front wheels, ideally in front, because as you jack up the rear of the car, the weight will shift forwards. Crack the nuts of your rear wheels both sides before you jack the car up. Jack up the rear axle and put your chassis stands under the u-bolt brackets. and rest the rear axle on that. Make sure the handbrake is off.

pull the wheel off the side you're working on. i put the wheel down in a manner that i could sit on it as i worked. with the wheel off, you're presented with the Drum Hub.

The hub might be held on with some small screws, or not, either way, the hub might be a little hard to remove. if it is difficult, give it a few good hits with the hammer to loosen it up and pull the drum off.

after pulling the drum off, hose the entire drum out. brake dust is quite bad for your health, DON'T USE A BRUSH. the hose is your best option.

This is what a drum brake looks like. The first step is to loosen off the braking system so you can remove everything, the method i used is to lift the little holding pin and use the needle-nose pliers to wind the shoe adjuster back to remove tension from the springs.